Mar 29,2024

Mar 29,2024

BSL

BSL

The zipper is composed of chain elements, sliders, upper and lower stops (front and rear codes), or locking parts. The chain elements are the key part, which directly determines the side pull strength of the zipper. Generally, a zipper has two chain belts, each chain belt has a row of chain elements, and the two rows of chain teeth are staggered with each other. The slider clamps the chain elements on both sides and slides with the help of the pull tab to engage or disengage the chain elements on both sides.

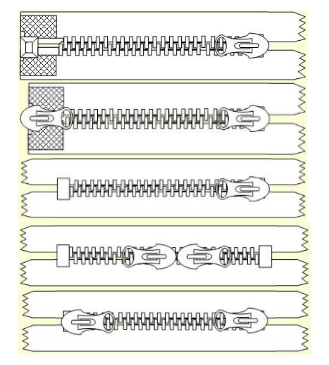

Open tail, double open tail, closed tail, "O" type double closed tail, "X" type double closed tail.

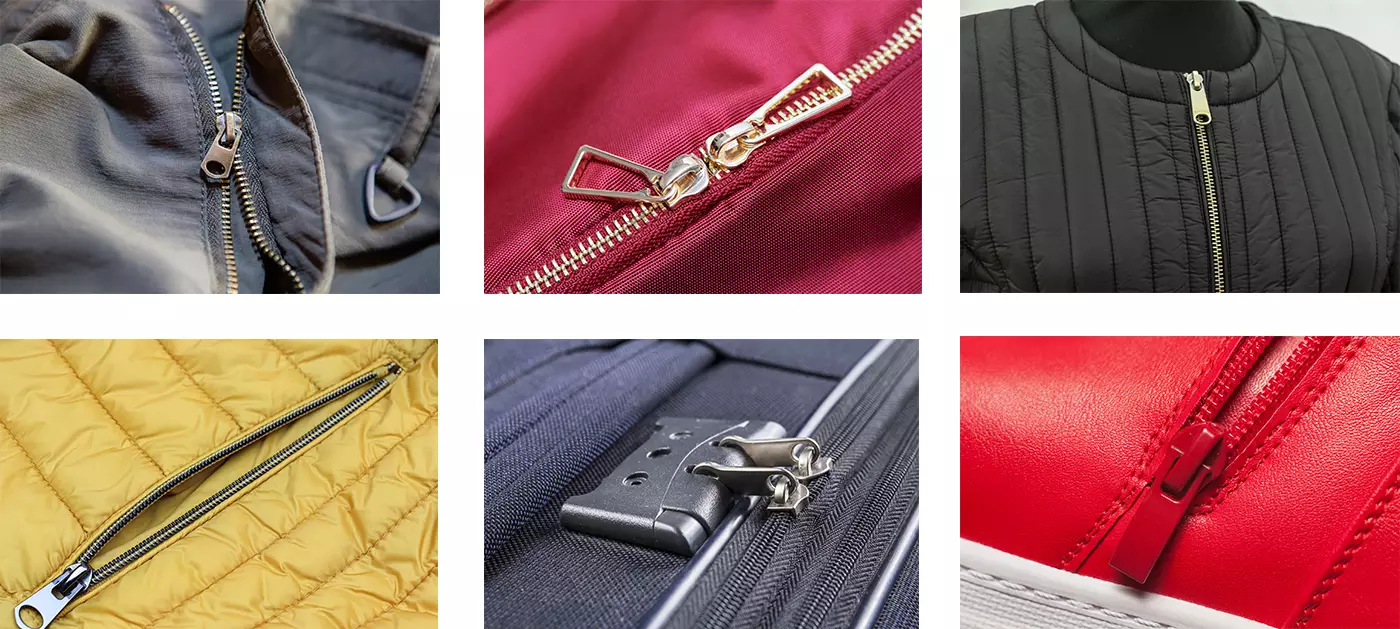

Metal zipper, nylon zipper, plastic zipper.

Such as invisible zippers, waterproof zippers, diving zippers, flame-retardant zippers, fire-resistant zippers, reinforced zippers, double-bone zippers, medical zippers, shoe zippers, etc.

Concept:

Anti-nickel: ANTI-Nickel---the amount of nickel released has no impact on human skin

Nickel Free: Nickel Free--- nickel-free

Effects of nickel on the human body:

Nickel comes into contact with human skin, making the skin think that an "imaginary enemy" has invaded, and secretes a certain substance to resist, which manifests as skin allergies, rashes, itching, etc.

Standard:

The EN1811 standard stipulates that the nickel release amount is ≤0.5ug/cm2.week

Nickel resistance inspection method:

Rub the mixture A and B for 30 seconds to see if it turns red.

Light-colored fabrics:

Light-colored fabrics cannot be in direct contact with red, black zippers and aluminum alloy zippers

Coated fabric:

PU, PVC, and other coatings cannot be in direct contact with dark-colored zippers

Leather fabric:

Chemical components in leather must be removed

Rough surface, thread surface:

Do not use a zipper that is too small and the thread must be cut cleanly.

For shoes:

Injection molded zippers cannot be used, and strength requirements are specifically stated.

During the sewing process, the pressure plate deforms the slider, making it difficult or even impossible to pull.

During the sewing process, the pressure plate hits the pull tab, which will cause the surface coating to fall off.

When sewing the zipper, there is not enough passage for the slider, causing the slider to get stuck. When pulling it forcefully, Chain teeth are scratched.

Slider wear during garment dyeing

When garments are dyed, the aluminum teeth are corroded by acid and alkali and undergo chemical changes, causing belly rupture.

When garments are dyed, sliders, squares, etc. are corroded by chemicals added.

If the garments are not washed after being dyed, the remaining chemicals will be reduced and decomposed by the metal.

During the water washing process, the paint on the surface of the slider was rubbed by the stainless steel hole wall of the inner tank of the water washing machine, causing paint wear.

(The electroplated slider is worn and the bottom copper is exposed)

When washing, the zipper is not closed and the slider is forced to move, causing damage to the square, chain elements, bottom stop, and other components.

The protective layer on the surface of metal zipper elements dissolves when heated, leaving stains on the fabric.

The double pins of the injection molded zipper will dissolve when exposed to high temperatures when ironed, and the slider will fall off from there.

Chemical substances in the fabric corrode the slider, causing it to rust, The zipper shrinks after steam ironing.